Filter section:

- Bulk solid silo

- Cement storage

- Coil lines, Inspection lines

- Coil storage

- Coiling machines

- Container ports

- Conveyor belt

- Decapper

- Engineering

- Extruder

- Filling plant

- Final assembly

- Finishing, Slitting line, Winder

- Finishing, Slitting lines

- Flying saw

- Forge hammer

- Gantry cranes

- Hot objects

- Laboratory

- Packing

- Ports, docking systems

- Printing machine, banderoling machine, register control

- Quality assurance

- Railway, Transportation

- Research and Development

- Service, Commissioning, Research

- Skin pass level, degree of stretching, mass flow

- Slitting shears

- Steel billets

- Tube inspection lines

Filter task:

- Abrasion measurement

- Coating inspection

- Coating inspection of foam material

- Collision avoidance

- Color inspection

- Color mark detection

- Color measurement of salmon meat

- Control of shears

- Distance measurement

- Egg yolk color classification

- Fill level measurement

- Length measurement

- Measurement of impact energy

- Mobile velocity and length measurement

- PET preform inspection

- Position detection

- Positioning of containers in gantry cranes

- Presence check

- Print mark detection

- Sandwich counter

- Velocity Measurement

- Velocity measurement, Length measurement

Filter measured variable:

- Acceleration (VLM)

- Color (CR)

- Degree of stretching and Skin pass level (VLM)

- Diameter (LDM)

- Distance (LDM)

- Fill level (LDM)

- Impact energy (VLM)

- Length (LDM)

- Length (VLM)

- Position (CR)

- Position (LDM)

- Position (VLM)

- Position detection (CR)

- Presence (CR)

- Presence (LDM)

- Quantity (CR)

- Thickness (LDM)

- Velocity (VLM)

- Velocity 1 (LDM)

- Velocity 2 (LDM)

- Width (LDM)

Task:

Velocity measurement, Length measurement

Areas:

Tube inspection lines

Measured Variables:

Velocity (VLM)

Length (VLM)

Acceleration (VLM)

Velocity measurement, Length measurement

Areas:

Tube inspection lines

Measured Variables:

Velocity (VLM)

Length (VLM)

Acceleration (VLM)

Description:

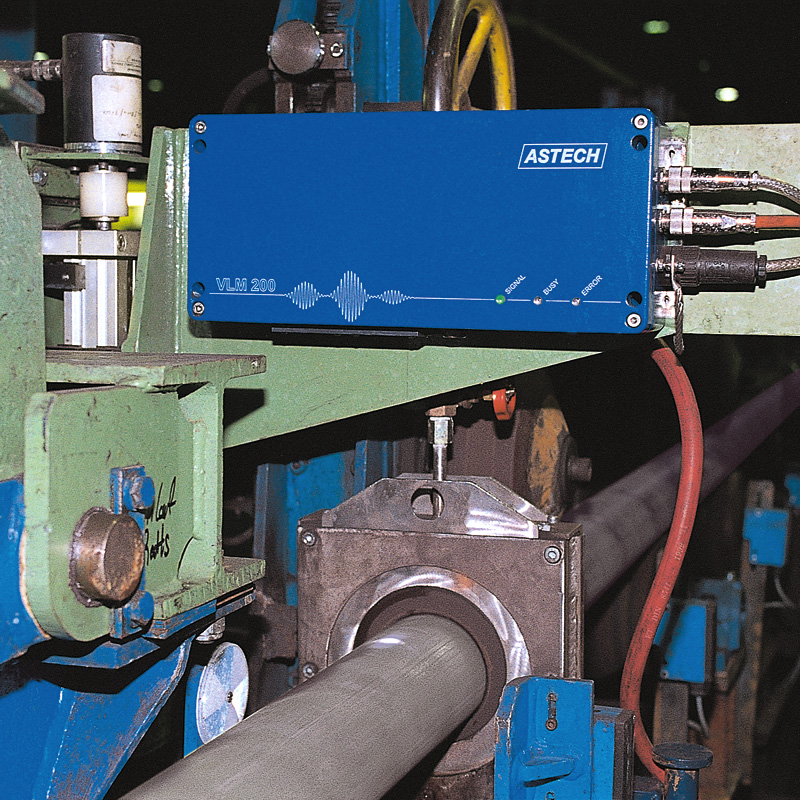

Ultrasonic and eddy-current testing systems for tubes and profiles require the speed of an object in order to synchronize the test probes on the moving objects. As individual objects pass the inspection line, the use of tactile measuring wheels would be very complex and failure-prone. The VLM operates optically and contact-free and records the speed of the object slip-free and precisely from the distance. At the same time the devices can determine the length of the object. The nature of the object’s surface does not have an influence on the measurement.

Products: VLM500, VLM500-MID, VLM502, VLM60

Ultrasonic and eddy-current testing systems for tubes and profiles require the speed of an object in order to synchronize the test probes on the moving objects. As individual objects pass the inspection line, the use of tactile measuring wheels would be very complex and failure-prone. The VLM operates optically and contact-free and records the speed of the object slip-free and precisely from the distance. At the same time the devices can determine the length of the object. The nature of the object’s surface does not have an influence on the measurement.

Products: VLM500, VLM500-MID, VLM502, VLM60